Introduction

Selecting the right plotter or cutter can make or break your production efficiency. Whether you run a small workshop or a large manufacturing plant, investing in the right technology ensures precision, speed, and lower material waste.

This guide will help you identify what to look for, compare types of machines, and understand how to maximize your investment.

1. Why Plotters & Cutters Matter in Textile Manufacturing

Plotters and cutters have evolved beyond simple sign-making or craft use: they are now core tools for textile, apparel, footwear, upholstery and industrial fabric producers. According to industry review sites, major factors include precision, repeatability, speed and versatility.

These machines allow you to:

- Print or plot patterns, markers and lay-plans with high accuracy.

- Cut fabrics, composites or multilayers cleanly and efficiently.

- Reduce manual labour, minimise waste and improve throughput.

- Adapt to a variety of materials (textiles, leather, composites, vinyl) and formats.

2. Key Factors to Evaluate Before Buying

Here are the essential considerations when selecting a plotter or cutter:

a) Production volume & format

Define your throughput, roll width, sheet size, layers and fabric types. Higher volumes require wider machines and more robust build.

b) Materials & compatibility

What materials will you cut or print? Vinyl, heat-seal film, leather, multi-layer textiles? The machine must handle the thickness and substrate.

c) Cutting/printing technology

- Cutting pressure capability (the more material types you want to handle, the higher the pressure needed)

- Blade type, rotary vs drag, flatbed vs roll-fed.

- For printing/plotting: print resolution, colour gamut, media feed.

- Software & driver compatibility: Check that the plotter works with your CAD formats (PLT, HPGL) and your existing pattern software. (Relevant to Velocity Plotters’ offering.)

d) Workflow & integration. Does the machine integrate with your CAD system (e.g., Audaces CAD, Gerber, Lectra, etc.)? The ease of file hand-off matters.

Do you need printing first, then cutting? (In many cases machines perform one function then the other.)

Is automation (nesting/merging/splitting) included? (Your company’s Control Center driver is a differentiator.)

e) Total cost & ROI

Beyond purchase price: shipping, import duties, installation, consumables (blades, heads, maintenance), operator training.

Look at ROI: labour savings, waste reduction, defect rate improvement.

f) After-sales support & lifecycle

Spare parts availability, maintenance frequency, warranty and service network are critical. A cheap machine with poor support ends up costing more.

3. Technical Specifications You Must Check

When reviewing machine specs, here are the key parameters to consider:

- Cutting/plotting width: Determines the maximum roll or sheet size the machine can handle.

- Cutting force / pressure: The required force depends on the type and thickness of the material you plan to cut. If in doubt, request a demo to make sure the machine can handle your materials properly.

- Cutting/plotting speed & accuracy: Evaluate these parameters based on your production volume. If you require high throughput, look for models that combine greater speed with precision to maintain consistent quality.

- Media feed type: roll-fed, flatbed, multi-layer, or vacuum table.

- Supported file formats & software compatibility: (PLT, HPGL, DXF, DWG, PDF, etc.)

- Automation features: nesting, merging/splitting, automatic job recognition (barcode/scanner).

- Operator ergonomics & safety features: Accessible maintenance, blade access, debris management.

- Serviceability & consumables: Blade change time, availability of spare parts, and service network coverage.

- Footprint & shipping/installation constraints: Machine weight, crate size, power requirements, and ventilation needs.

4. Plotter vs. Cutter: Which One Do You Really Need?

Although the terms plotter and cutter are sometimes used interchangeably, there are important differences between them — and understanding these distinctions will help you make the right investment for your production needs.

Plotter:

A plotter is primarily used to print or trace vector lines such as pattern outlines, markers, and annotations. However, some advanced plotter models can also cut patterns directly on various materials — from standard plotter paper and kraft paper to thicker media such as: Thick cardboard, PVC sheets, Rigid plastics, Industrial textiles, Paper, canvas, vinyl, and more

This versatility makes the plotter ideal for design validation, pattern testing, and prototype creation before mass production.

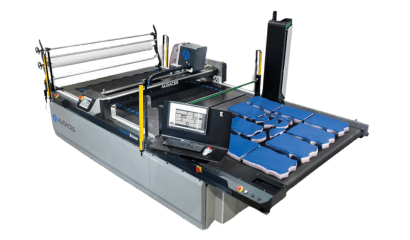

Automatic Cutter:

A cutter, on the other hand, is specifically designed for precision cutting of materials like fabrics, composites, multi-layer textiles, leather, and technical materials. Its main goal is to optimize speed and accuracy in production environments where high-volume cutting is essential.

In textile manufacturing, your setup might include:

- A plotter dedicated to printing or plotting patterns and markers before cutting.

- An integrated plotter-cutter that can perform both operations — printing and cutting — in sequence, depending on your workflow and production strategy.

- An automatic fabric cutting machine, which uses advanced control systems, vacuum tables, and blade or oscillating tools to cut multiple or single fabric layers simultaneously with speed and consistency. This is ideal for manufacturers seeking high efficiency, material savings, and precise repeatability in their production lines.

How to Decide Which One You Need:

Your choice between a dedicated cutter and an integrated plotter-cutter depends on your production volume, material type, and workflow flexibility.

- If your focus is on heavy-duty cutting (multi-layer fabrics, technical textiles, composites, or leather), a dedicated automatic cutter is the best solution.

- If you also need to plot patterns, markers, or annotations and require greater flexibility, consider a hybrid plotter-cutter or a separate plotter and cutter configuration to adapt to different tasks.

- Finally, check your software compatibility before purchasing. Ensure the equipment supports standard CAD file formats such as PLT, HPGL, DXF, or PDF.

All Velocity Plotters solutions are fully compatible with leading CAD systems, ensuring smooth integration into your digital workflow.

5. Workflow Integration: CAD, File Formats & Software

CAD compatibility: Your machine should read files from systems like Gerber AccuMark, OptiTex, Lectra, or StyleCAD.

File formats: Support for PLT, HPGL, HPG is essential.

Driver features: Tools such as rotation, merging, splitting, and nesting optimize your workflow and material use.

Automation: Look for barcode reading, network connection, and automatic file import capabilities.

Ease of use: Proper operator training and digital data management ensure consistent results

6. Cost, Shipping & Installation Considerations

Beyond the machine’s price, consider the total cost of ownership. Factors like shipping, customs, installation, and training can significantly impact your budget.

Check freight dimensions, weight, and packaging requirements, especially for large or heavy equipment. Confirm power and space needs before delivery to ensure smooth setup.

Finally, choose suppliers that provide local technical support, spare parts availability, and remote assistance — this ensures long-term reliability and faster problem resolution.

7. Maintenance, Support & Lifecycle

To maximize ROI, look beyond the initial purchase. Establish a preventive maintenance routine (cleaning, blade replacement, calibration checks) and ensure spare parts are readily available.

Keep your machine’s software and firmware updated, and confirm you’ll have reliable local or remote technical support.

Finally, remember that a high-quality plotter or cutter can last 10-15 years with proper care — making it a smart long-term investment

Closing

Choosing the right plotter or cutter is a strategic decision that directly affects your production efficiency, material usage, and profitability. By carefully evaluating your needs, workflow, materials, and cost-benefit balance, you can confidently select the solution that best fits your business.

If you’d like expert guidance, the Velocity Plotters team is here to help. We’ll analyze your production goals, recommend the ideal configuration for your workflow, and guide you toward the most efficient and cost-effective setup.

👉 Visit www.velocityplotters.com to learn more and get personalized advice from our specialists.