Introduction. What is Garment Manufacturing?

Garment manufacturing is one of the most dynamic and complex industries in the world, combining creativity, precision, and advanced technology. From the first sketch to the finished garment, the process requires a series of carefully planned steps that ensure both quality and efficiency. In this guide, we’ll walk through the key stages of garment manufacturing and highlight how Velocity Plotters’ innovative solutions help companies optimize their production, reduce costs, and remain competitive in today’s fast-paced market.

Key Stages of Garment Manufacturing

- Concept & Design – The process begins with creative ideas transformed into digital sketches using CAD software.

- Pattern Making – Patterns are developed as the blueprint of the garment, either created digitally or digitized with tools like Velocity’s V-Shoot.

- Grading – Patterns are resized to create different sizes, ensuring proportional accuracy across the size range.

- Marker Making – Markers are planned to optimize fabric usage and reduce waste during cutting.

- Fabric Spreading – Fabric layers are spread on cutting tables, prepared for precise cutting operations.

- Cutting – Fabrics are cut with advanced solutions such as pattern plotter cutters, flatbeds, or the ProCut-X Single Ply Automatic Cutter.

- Sewing & Assembly – Cut pieces are stitched together, with accuracy from earlier stages ensuring smooth assembly.

- Finishing – Garments are pressed, labeled, packaged, and quality-checked before reaching the market.

1. Concept & Design

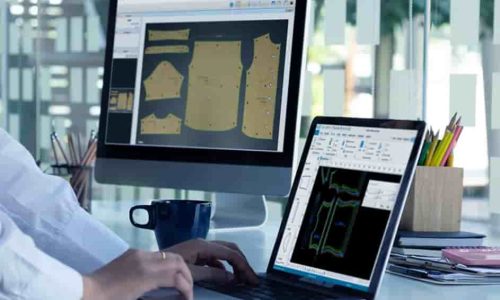

The journey begins with an idea. Designers conceptualize styles based on market research, fashion trends, and customer preferences. CAD software like Audaces enables precise digital designs, ensuring accuracy and speed from the very first step.

2. Pattern Making

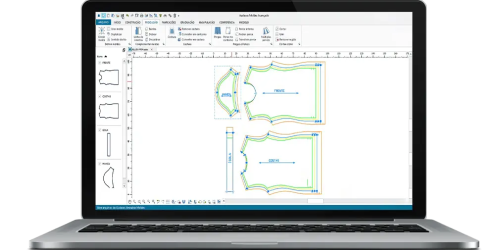

Once the design is finalized, patterns are created to serve as the blueprint for each garment. Traditionally, patterns were drawn manually, but with digitization tools like Velocity’s V-Shoot Camera Digitizer, physical patterns can be quickly converted into digital files for editing, storing, and production.

3. Grading

Patterns are graded to create different sizes. CAD systems simplify this process, ensuring consistent proportions across all sizes while saving valuable time compared to manual grading.

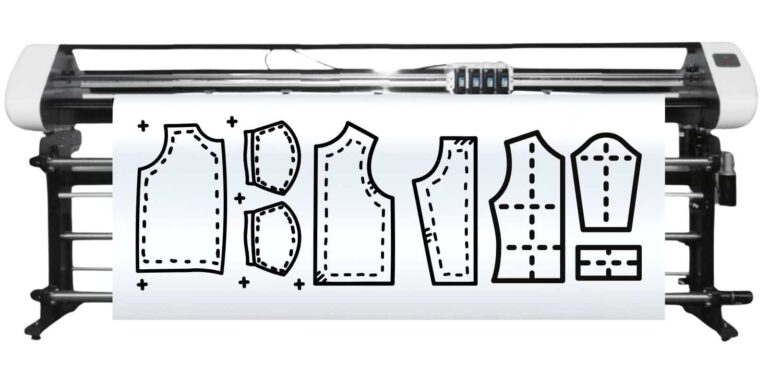

4. Marker Making

Markers determine how fabric will be cut with minimal waste. Precision is critical here. Velocity Plotters’ marker plotters, available with one, two, or even four printheads, allow for high-speed, accurate marker plotting. More printheads mean faster plotting, making them ideal for large-scale production environments.

5. Fabric Spreading

Fabric is spread on long cutting tables, either manually or with automated spreading equipment, to prepare for the cutting stage. Proper spreading reduces errors and ensures efficient fabric utilization.

6. Cutting

Cutting is one of the most decisive stages in garment manufacturing. Velocity offers a wide range of cutting solutions:

- Pattern Plotter Cutters (All-in-One): These machines can both print and cut patterns, streamlining workflow and reducing handling time.

- Flatbed Cutting Tables: Ideal for flexible, detailed, and precise cuts across different materials.

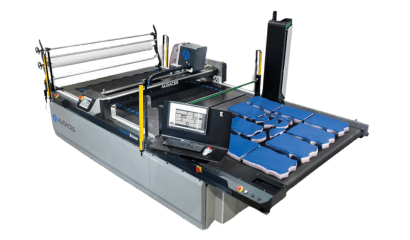

- Single Ply Automatic Cutter ProCut-X: A robust, high-performance machine designed for maximum speed, precision, and durability. It is perfect for manufacturers that demand top-tier productivity, as it can handle intricate designs and multiple fabric types with unmatched reliability

- High-Ply Automatic Cutting Machine: An advanced multi-layer cutting solution built for high-volume production. It delivers exceptional speed, accuracy, and consistency when cutting large stacks of fabric, making it ideal for mass manufacturing. This machine ensures maximum efficiency by reducing manual labor, minimizing material waste, and maintaining precision across every layer.

7. Sewing & Assembly

Cut fabric pieces are passed on to sewing operators who stitch them together using industrial sewing machines. The accuracy of cutting and marking from earlier stages ensures that sewing lines up correctly, reducing errors and rework.

8. Finishing

Once assembled, garments go through pressing, labeling, and packaging. Quality control checks are performed to guarantee the finished product meets brand standards.

Technology That Transforms the Process

At every step of garment manufacturing, technology is the game-changer. This is where Velocity Plotters comes in with a comprehensive suite of solutions tailored for the apparel and textile industry:

- Pattern Plotters for accurate blueprint printing.

- Marker Plotters (1–4 printheads) for fast, large-scale marker plotting.

- Pattern Plotter Cutters (all-in-one machines that print and cut).

- Flatbed Cutting Tables for precision cutting across diverse materials.

- Single Ply Automatic Cutter ProCut-X, a robust machine that maximizes efficiency and quality in cutting.

- V-Shoot Camera Digitizer, which digitizes physical patterns into editable digital files in minutes.

- Audaces CAD Software for professional design, pattern making, grading, and marker optimization.

- File Conversion Software for converting DXF or DWG into compatible plotter formats.

These tools help manufacturers boost productivity, reduce waste, and maintain precision, ensuring seamless integration from design to final production.

Conclusion

Garment manufacturing is a fascinating blend of art and engineering. With the right strategies and advanced technologies, apparel companies can transform challenges into opportunities for growth. By partnering with Velocity Plotters, manufacturers gain access to innovative solutions that enhance speed, precision, and profitability—helping them stay ahead in today’s competitive global market.