In 2025, the fashion and textile industry is facing a major shift. With rising import tariffs, global supply chain instability, and growing demand for personalized, locally made products, brands that once relied on overseas manufacturing are being forced to rethink their strategies.

However, for those adopting automation, digital pattern design, y advanced cutting and printing technology, this is not a crisis—it’s an opportunity.

At Plotters Velocity, we believe this change represents the beginning of a smarter, more sustainable, and profitable manufacturing era.

1. Tariffs and Imports: A New Reality for Fashion

Tariffs are government-imposed taxes on imported goods. In recent years, tariff increases have dramatically impacted the apparel, textile, and leather goods industries.

According to FABRIC Incubator, recent U.S. import fees have raised production costs by up to 124% on certain products, making offshore manufacturing increasingly unfeasible.

Brands now face:

Rising import costs and shrinking profit margins.

Delays and unpredictability in customs and logistics.

A growing need for faster, more flexible production models.

This has sparked a new movement toward domestic manufacturing y nearshoring, where brands produce closer to home to control costs, quality, and time-to-market.

2. Reshoring + Automation = Competitive Advantage

Reshoring isn’t just a trend — it’s a long-term strategy.

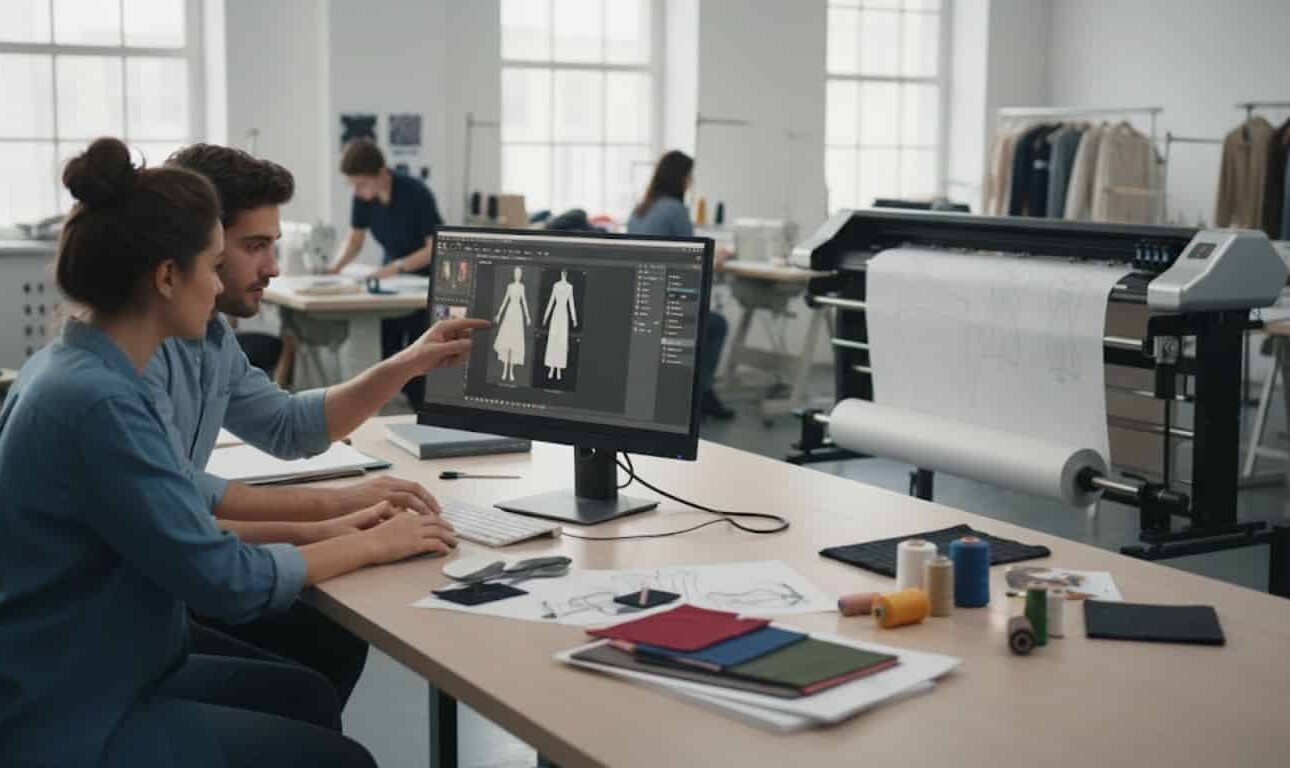

To make local production viable, factories must embrace digital transformation through automation and smart technologies.

Key tools include:

CAD design and pattern-making software (like Audaces) to speed up and simplify development.

Printing and cutting plotters that allow you to print and cut markers or templates directly on paper.

Automatic single-ply and multi-ply cutters for precision and consistency.

Pattern digitizing systems to convert physical templates into editable digital files.

Automated workflows that connect design, printing, and cutting for full production efficiency.

With these solutions, factories can produce small batches, custom designs, and high-value products quickly and profitably — turning local production into a real competitive advantage.

3. The Rise of Personalization: The New Definition of Luxury

Consumers are increasingly valuing authenticity, craftsmanship, and personalization.

This is especially true in the leather goods, fashion accessories, y custom garment industries.

As Maker’s Row points out, U.S. brands are willing to pay more for custom, limited-edition products made locally, driving strong demand for factories capable of flexible, small-scale production.

Here’s why this shift matters:

Higher margins with lower volume.

Steady, year-round demand not tied to fashion seasons.

More control and reduced risk compared to overseas sourcing.

Consumer preference for “Made in USA” or locally made products.

Transferable skills — sewing, cutting, and pattern-making can easily adapt to new product categories like leather goods or accessories.

4. Velocity Plotters: Technology Driving the New Manufacturing Era

To compete in this evolving landscape, manufacturers need technology that is reliable, efficient, and versatile.

Plotters Velocity provides cutting-edge solutions designed to optimize every stage of fashion, furniture, footwear, and leather goods production:

Printing and cutting plotters (1, 2, or 4 heads) for high-speed, high-precision output.

Automatic fabric cutters, both single ply y multi ply, for clean, consistent cuts.

Pattern digitizing systems to transform physical patterns into editable digital formats.

Audaces CAD software for digital design, grading, and pattern development.

Easy Plot conversion software, compatible with formats like PLT, HPGL, DXF, and PDF.

These tools enable you to:

Reduce labor and preparation time.

Increase material utilization and precision.

Deliver faster responses to custom or small-batch orders.

Expand into new, profitable markets like custom leather and personalized goods.

Conclusión

The global fashion landscape is evolving.

Rising tariffs and shifting consumer values are accelerating the transition to domestic, tech-driven, and personalized production.

With Velocity Plotters’ technology, your factory can become more efficient, flexible, and profitable — ready to meet the future of manufacturing head-on.